雙組份打膠機(jī)切換膠水清潔全流程解析

時(shí)間:2025-06-05 來(lái)源:http://www.niepanwow.com/ 發(fā)布人:昌盛機(jī)械

雙組份打膠機(jī)因能精準(zhǔn)混合A、B兩組份膠水,廣泛應(yīng)用于建筑密封、汽車(chē)制造等領(lǐng)域。當(dāng)生產(chǎn)需求變更需切換不同膠水時(shí),徹底清潔設(shè)備是保障后續(xù)生產(chǎn)質(zhì)量的關(guān)鍵。以下從操作步驟、材料選擇到驗(yàn)收標(biāo)準(zhǔn),系統(tǒng)闡述清潔全流程。

The two-component glue machine is widely used in fields such as building sealing and automotive manufacturing due to its ability to accurately mix adhesive of components A and B. Thoroughly cleaning the equipment is the key to ensuring the quality of subsequent production when different adhesives need to be switched due to changes in production requirements. The following systematically explains the entire cleaning process from operational steps, material selection to acceptance criteria.

一、清潔前準(zhǔn)備:精準(zhǔn)匹配清洗劑

1、 Preparation before cleaning: precise matching of cleaning agents

需根據(jù)原膠水與新膠水的化學(xué)特性選擇清洗劑。例如,聚氨酯膠水推薦使用醋酸乙酯或丙酮,而環(huán)氧樹(shù)脂膠則需專(zhuān)用環(huán)氧清洗劑。清洗前需關(guān)閉AB料桶底部閥門(mén),防止殘膠倒流污染清洗劑。

The cleaning agent should be selected based on the chemical properties of the original adhesive and the new adhesive. For example, polyurethane adhesive is recommended to use ethyl acetate or acetone, while epoxy resin adhesive requires a specialized epoxy cleaning agent. Before cleaning, it is necessary to close the bottom valve of the AB material bucket to prevent residual glue from flowing back and contaminating the cleaning agent.

二、核心清潔步驟:從管路到泵體的深度清理

2、 Core cleaning steps: Deep cleaning from pipeline to pump body

排出殘膠:?jiǎn)?dòng)設(shè)備,將膠閥、高壓鐵氟龍管及AB泵內(nèi)殘膠完全排出。需觀(guān)察膠閥出膠口膠量變化,當(dāng)膠液顏色由混合色轉(zhuǎn)為單一組份原色時(shí),表明殘膠已排空。

Discharge residual glue: Start the equipment and completely discharge the residual glue from the glue valve, high-pressure PTFE tube, and AB pump. It is necessary to observe the change in the amount of glue at the outlet of the glue valve. When the color of the glue liquid changes from a mixed color to a single component original color, it indicates that the residual glue has been emptied.

拆卸清洗料桶:關(guān)閉設(shè)備總電源,拆開(kāi)料桶底部膠管,將剩余膠水徹底排出。用蘸有清洗劑的干凈抹布擦拭料桶內(nèi)壁,重點(diǎn)清除桶底與桶壁交界處的膠漬。

Disassemble and clean the material bucket: Turn off the main power of the equipment, remove the rubber hose at the bottom of the material bucket, and completely drain the remaining glue. Wipe the inner wall of the material bucket with a clean cloth dipped in cleaning agent, focusing on removing the glue stains at the junction of the bucket bottom and the bucket wall.

深度清潔泵體:拆下AB泵,由專(zhuān)業(yè)人員清理泵腔內(nèi)殘留膠水。需注意,泵體內(nèi)部齒輪與密封圈為精密部件,需用軟毛刷蘸取清洗劑輕柔刷洗,避免劃傷。

Deep cleaning of pump body: Remove the AB pump and have a professional clean the residual glue inside the pump chamber. Please note that the gears and sealing rings inside the pump body are precision components and should be gently brushed with a soft bristled brush dipped in cleaning agent to avoid scratches.

更換耗材:高壓鐵氟龍管因內(nèi)壁易附著膠漬,需每次換膠時(shí)更換。靜態(tài)混合管雖可重復(fù)使用,但需用清洗劑浸泡后氣槍吹掃。

Replacement of consumables: High pressure PTFE pipes are prone to adhesive stains on the inner wall and need to be replaced every time the adhesive is changed. Although the static mixing tube can be reused, it needs to be soaked in cleaning agent and blown with an air gun.

三、驗(yàn)收與測(cè)試:三重驗(yàn)證確保清潔度

3、 Acceptance and Testing: Triple Validation to Ensure Cleanliness

視覺(jué)檢查:用強(qiáng)光手電筒照射管路內(nèi)壁,無(wú)膠漬殘留且呈現(xiàn)金屬本色為合格。

Visual inspection: Use a strong flashlight to illuminate the inner wall of the pipeline. If there are no adhesive residue and the metal color appears, it is qualified.

壓力測(cè)試:重新組裝后,向設(shè)備內(nèi)注入清洗劑,啟動(dòng)設(shè)備觀(guān)察壓力表。若壓力穩(wěn)定在正常工作范圍內(nèi),表明管路無(wú)堵塞。

Pressure test: After reassembling, inject cleaning agent into the equipment and start the equipment to observe the pressure gauge. If the pressure remains stable within the normal operating range, it indicates that the pipeline is not blocked.

試機(jī)驗(yàn)證:倒入新膠水,點(diǎn)動(dòng)出膠3-5分鐘,檢查出膠顏色是否均勻,并取樣送檢膠水混合比例。

Test machine verification: Pour in new glue, tap the glue for 3-5 minutes, check if the color of the glue is uniform, and take a sample to check the mixing ratio of the glue.

四、特殊場(chǎng)景處理:應(yīng)對(duì)頑固膠漬與長(zhǎng)時(shí)間停機(jī)

4、 Special scenario handling: Dealing with stubborn glue stains and prolonged downtime

頑固膠漬:若管路內(nèi)有固化膠塊,可用加熱帶將管路包裹,加熱至60℃使膠體軟化,再配合清洗劑沖洗。

Stubborn glue stains: If there are solidified glue blocks in the pipeline, the pipeline can be wrapped with a heating belt, heated to 60 ℃ to soften the glue, and then rinsed with a cleaning agent.

長(zhǎng)期停機(jī):若設(shè)備停用超10天,需將儲(chǔ)膠桶內(nèi)清洗劑排空,用氣槍將管路吹干,并在出膠口涂抹防銹油。

Long term shutdown: If the equipment is stopped for more than 10 days, the cleaning agent in the rubber storage tank should be emptied, the pipeline should be dried with an air gun, and rust proof oil should be applied to the rubber outlet.

五、維護(hù)保養(yǎng):延長(zhǎng)設(shè)備壽命的關(guān)鍵舉措

5、 Maintenance and upkeep: key measures to extend equipment lifespan

日常維護(hù):每班次結(jié)束后,用清洗劑擦拭機(jī)身,排放油水分離器積水。

Daily maintenance: After each shift, wipe the machine body with cleaning agent and drain the accumulated water in the oil-water separator.

定期保養(yǎng):每周檢查氣路油霧器油位,每月清洗過(guò)濾器與針閥,每年對(duì)主泵進(jìn)行解體清洗。

Regular maintenance: Check the oil level of the air path oil mist device weekly, clean the filter and needle valve monthly, and disassemble and clean the main pump annually.

通過(guò)嚴(yán)格執(zhí)行上述流程,可確保雙組份打膠機(jī)在膠水切換后穩(wěn)定運(yùn)行。實(shí)際案例表明,規(guī)范清潔能使設(shè)備故障率降低,膠水切換時(shí)間縮短。企業(yè)可結(jié)合自身生產(chǎn)節(jié)拍,制定標(biāo)準(zhǔn)化清潔作業(yè)指導(dǎo)書(shū),并培訓(xùn)操作人員通過(guò)認(rèn)證,從而構(gòu)建完善的設(shè)備管理體系。

By strictly following the above process, the two-component gluing machine can ensure stable operation after glue switching. Practical cases have shown that standardized cleaning can reduce equipment failure rates and shorten glue switching times. Enterprises can develop standardized cleaning operation manuals based on their own production pace, and train operators to pass certification, thereby building a comprehensive equipment management system.

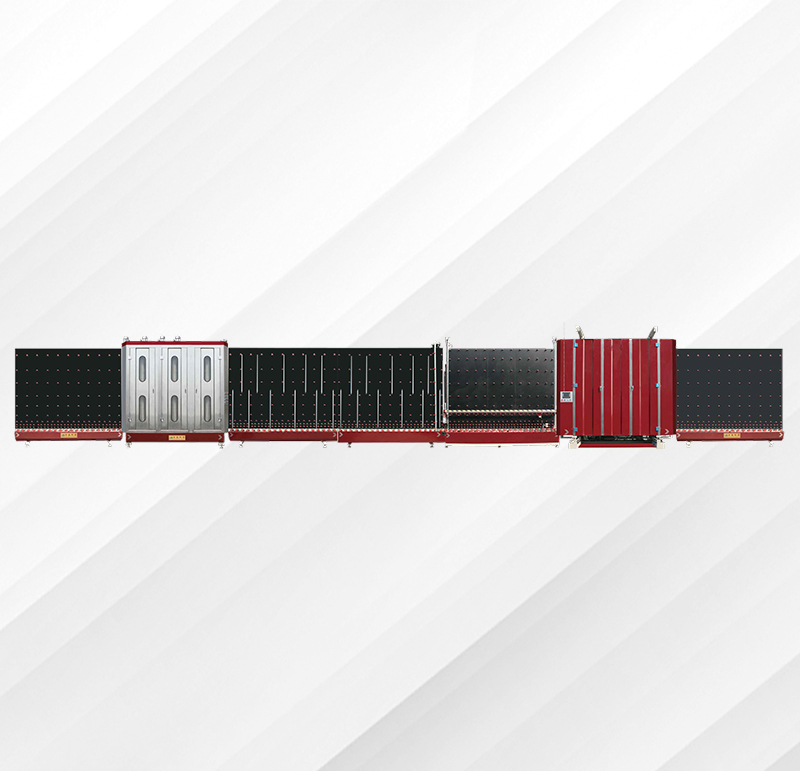

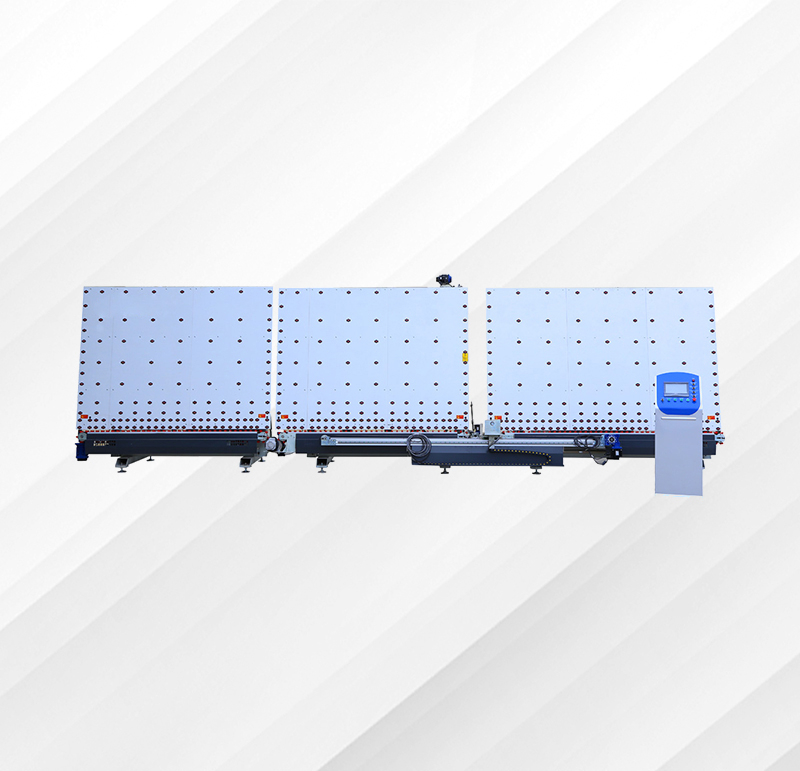

本文由全自動(dòng)封膠線(xiàn)友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊:http://www.niepanwow.com我們將會(huì)對(duì)您提出的疑問(wèn)進(jìn)行詳細(xì)的解答,歡迎您登錄網(wǎng)站留言.

This article is a friendly contribution from glass coating machine equipment For more information, please click: http://www.niepanwow.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 中空玻璃加工設(shè)備:立式與臥式清洗機(jī)的差異化解析 2025/06/06

- 雙組份打膠機(jī)切換膠水清潔全流程解析 2025/06/05

- 全自動(dòng)封膠線(xiàn)輔助傳送前限位是什么意思? 2025/06/04

- 雙組份打膠機(jī)是為解決什么問(wèn)題產(chǎn)生的呢? 2025/06/03

- 全自動(dòng)丁基膠涂布機(jī)操作注意事項(xiàng):細(xì)節(jié)決定品質(zhì)與效率 2025/05/27

- 雙組份打膠機(jī):解碼膠水混合后的固化時(shí)間控制藝術(shù) 2025/05/26

- 臥式丁基膠涂布機(jī)傳動(dòng)系統(tǒng)維護(hù)要點(diǎn)解析 2025/05/20

- 中空玻璃加工必備8大設(shè)備詳解 2025/05/19

- 全自動(dòng)鋁條折彎?rùn)C(jī)在工作中有什么優(yōu)勢(shì)? 2025/05/16

- 全自動(dòng)丁基膠涂布機(jī)在工業(yè)領(lǐng)域做出來(lái)什么優(yōu)化? 2025/05/14

產(chǎn)品分類(lèi)Product categories

產(chǎn)品分類(lèi)Product categories

聯(lián)系我們Contact us

聯(lián)系我們Contact us

- 咨詢(xún)熱線(xiàn):0531-85717458 13705446998

- 公司地址: 山東省德州市齊河安頭鄉(xiāng)企巢工業(yè)園

- 掃碼聯(lián)系我們:

當(dāng)前位置:

當(dāng)前位置: